An innovative technology for coral reef regeneration, the Reefbud, has already been embraced by tourist resorts in the Philippines, the land of its birth. Now a miniature version has been launched to make it more affordable and practical for small, remote fishing communities.

Now seven years old, the Reefbud is building a record of success where it is sorely needed. The Philippines’ 7,107 islands have an incredible 27,000 km2 of coral reefs, but they also have thousands of small fishing villages where illegal fishing methods have caused untold damage. In 2007, the Reef Check Foundation reported that only 5% of the Philippines’ reefs were in “excellent condition.”

Reefbud restoration programs are already making their mark in communities where local industries, in particular tourism, can afford full-size 450 kg models at $800 each. Now local NGO Biri Initiative Org. is producing a 150 kg Mini Reefbud that will be just as effective, but more affordable and capable of being deployed by just a couple of fishermen in a dugout canoe.

This July, Biri Initiative launched the “Reefbud Buddy” campaign to raise funds for the manufacturing and deployment of Mini Reefbuds. Priced at just $295, the first Mini Reefbuds will be deployed off Sabang Beach, Mindoro, to be followed by Biri Island in Northern Samar, but the plan in the next few years is to take them nationwide.

SIMPLE AND CHEAP

The Reefbud is the brainchild of the late Austrian geoscientist Dr. Harald Kremnitz and Filipino Benjamin Tayag, Jr. of the local Yes2Life Foundation.

Reefbuds combine two materials: concrete (75% by volume) to provide structural integrity, and a specially formulated biomass (25%). The concept was based on a process first developed in Europe, using materials not readily available in the tropics. It was then adapted to make the manufacturing of Reefbuds in the Philippines – or anywhere else in the world – both simple and cheap.

The result is a unique form of artificial reef with the following characteristics:

Porosity: Reefbuds absorb sea water much like a sponge. This has several benefits. (i) Together with the water, they also absorb microscopic marine life such as spores, plankton and algae. Even strong currents are not a problem since they simply drive the marine life into the Reefbud’s millions of cavities. (ii) The entire Reefbud takes on the pH of the surrounding ocean. (iii) The weight and aqua dynamic shape of the Reefbud mean it is already extremely stable, but after entering the water its weight increases by a further 30%, ensuring it provides a permanent home for marine life even in areas of strong currents.

Calcification: The blend of concrete and biomass reacts with sea water and triggers a process of calcification, the same process that naturally forms coral reefs, crustacean shells, turtle shells, etc.

Cheap, available materials: The concrete component of Reefbuds is made using beach sand and sea water, and the components of the biomass are readily available waste products such as coconut husks and rice stalks.

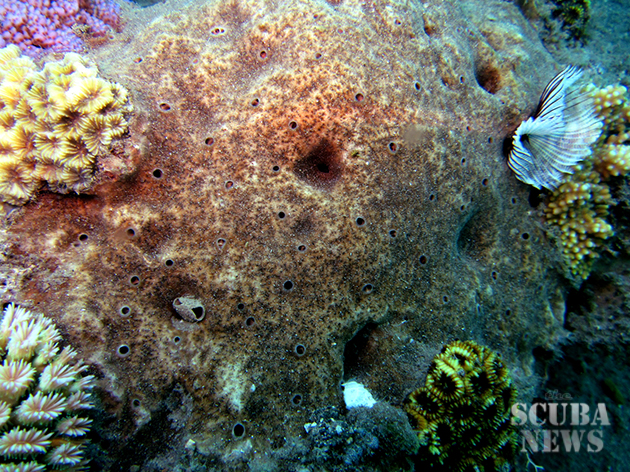

Speed of growth: The most spectacular feature of Reefbuds is the speed at which they are populated by marine life. In as little as eight weeks after deployment in a “marine dead” area (only sand and/or mud), they are home to algae, anemones, baby fish and squid, and a host of other wildlife.

REEFBUDS IN ACTION

In 2006, the Reefbud won a World Bank Country Development Marketplace competition, and in 2007 the first deployments were undertaken by Yes2Life, funded by the Philippines Australia Community Assistance Programs.

These first deployments took place in the popular diving location of Anilao, Batangas, and in 2010 a second batch were deployed there, bringing to 28 the total number of Reefbuds along this stretch of coastline.

The first large-scale project also began in 2007, in Rosario, Cavite, where several large corporations, spearheaded by Petron, funded the deployment of 1,200 Reefbuds. The main objective of the Rosario project was revitalize the local fishing industry, and in that it proved a resounding success, with fishermen and divers reporting larger numbers of fish, including species that had almost disappeared, and even the appearance of species that were previously unknown there.

So successful was the Rosario project that in 2012, the country’s leading destination for international tourists, Boracay Island, followed suit and embraced Reefbuds.

After declaring that 90% of its reefs were dead, Boracay launched project “Code Blue,” a hospital emergency code for a patient requiring immediate medical attention. With funding of P60 million (US$1.3 million) from the Loren Legarda Foundation, 5,000 Reefbuds were deployed along Boracay’s famed White Beach. According to project manager and Boracay advocate Ariel Abraham, the performance of the Reefbuds over the last two years has been an outstanding success.

In 2013, Biri Initiative deployed its first 50 Reefbuds, in association with Big Apple Initiative, at the popular tourist resort of Sabang Beach, Mindoro.

Also in 2013, another tourist destination, Camiguin Island, in the province of Misamis Oriental, received 300 Reefbuds, funded by the Department of Environment and Natural Resources.

Then in June 2014, Biri Initiative and Benjamin Tayag, Jr. conceived and began manufacturing the Mini Reefbud. The first 50 will be deployed at Sabang Beach in the coming months, alongside the full-size Reefbuds that are already proving effective there.

There are now no regulatory hurdles preventing a bright future for Reefbuds in the Philippines, since they exceed the standards and expectations of the Department of Science and Technology and the Department of the Environment and Natural Resources. If you would like to help coastal communities around the Philippines enjoy the benefits of Reefbuds, please contact Biri Initiative today to learn more about its Reefbud Buddy campaign.

Visit the Biri Initiative at: http://www.biri-initiative.org/