I recently received a call/e-mail from an instructor about an unsafe situation. She stated that one of her employees recently took a trip and had their SCUBA cylinders filled at a remote location. The other facility filled their cylinder to 5000 psi (345 BAR) when they were rated to 3000 psi (206 BAR). Her staff was obviously concerned and drained the cylinder to 2500 psi (172 BAR) the moment they recognized the mistake. However, that brought up the question of what to do next. Is the cylinder safe? Why didn’t the burst disk activate? What other concerns might there be?

The most obvious concern was that anyone would be careless enough to fill a cylinder that far beyond the rated pressure. The final pressure was obviously above the government approved rated service pressure and that facility violated a very clear rule (173.301a – USA). We could say that the facility operator should be chastised, but I don’t know how far that would go, or if they would understand their foolishness. I think it’s best that we focus on the positive, that the error was realized by a knowledgeable person and rectified as soon as possible.

Is the cylinder safe? There is no obvious way to tell. The only immediate recommendation I would have given was drain the cylinder to zero, not 2500. If the cylinder was weakened due to the over pressurization, 2500 psi (172 BAR) can still create a large explosive force.

The 5000 psi (345 BAR) is the hydrostatic requalification pressure of this specific cylinder. It’s nice that the facility tried to give them a free hydro, but they did not test the expansion or stamp the cylinder (This is a joke, for all you serious readers.) To determine if the cylinder is within standards it should be taken to an approved hydrotest facility for an inspection and testing. If the cylinder passes requalification there should be no further concerns.

Why didn’t the burst disk activate? Likely because it was doing its job. The burst disk is rated to the requalification pressure. Since this cylinder was pressurized to its requalification pressure, the burst disk was HOPEFULLY very close to rupturing. However, if it never exceeded the rated pressure, it’s not surprising that it did not activate. I would recommend replacing the burst disk to ensure its proper operation and to prevent a pre-mature rupture on the next fill.

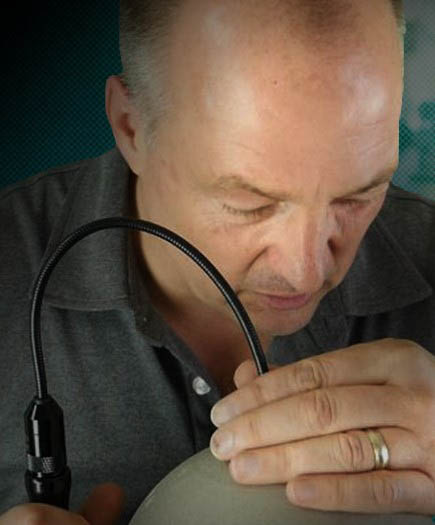

I would also spend some personal time conducting another visual inspection after the re-qualification. I would want to ensure that no issues developed so I would look closely at the threads, inspect the interior and test the valve. I would not expect anything to change, but it would give me peace of mind.

In conclusion, cylinders are engineered to high standards. They are built to withstand occasional abuse or foolish people. But they should not be taken for granted. Anytime you suspect a cylinder has been used outside its designed purpose, pull it form service for a full inspection by a trained inspector.