Cylinder Training Services has developed a new tool to help the inspector view a cylinder’s threads. Many inspectors use a light and mirror to inspect the threads of a cylinder. This procedure has been used for a long period of time but takes dedication and practice to master the techniques.

Using a light and mirror can also be problematic for people with diminishing eyesight. To overcome these issues Cylinder Training services has developed the Cylinder Thread Viewer.

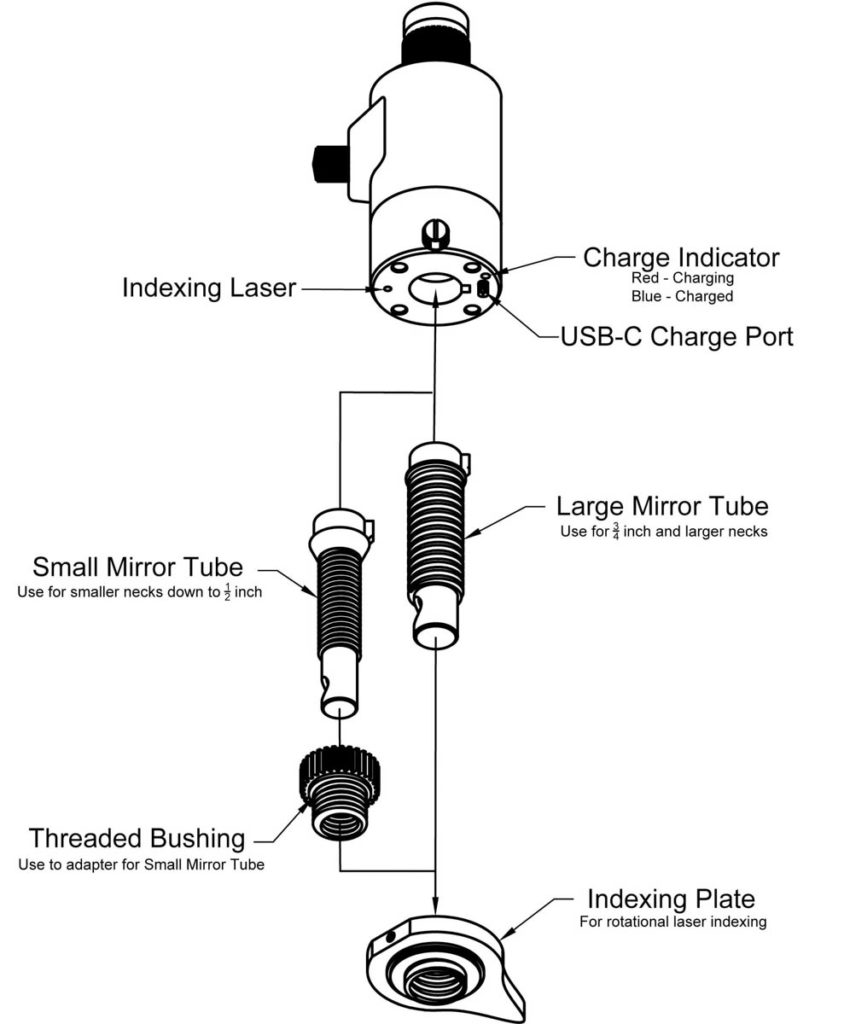

The Cylinder Thread Viewer helps the inspector by clarifying, magnifying, modifying, and simplifying the inspection process. This is all accomplished using a laser on an index plate, rechargeable battery, Glass lenses and interchangeable mirror tube sizes.

Clarify

The clarity of the threads is very important during the cylinder inspection process. The cylinder thread viewer uses an internal white LED light to shine into the peaks and valleys of the threads. The intensity of the LED light can be adjusted using the front Off/On knob. As the knob is turned on, the intensity of the light increases. If the light becomes too intense, the knob can be adjusted down, giving the inspector a customized view of the threads. The clarity of the threads can be focused, using the adjustable focus tube. The user can adjust the view based on their personal vision needs.

Magnify

Looking through focus tube, the Cylinder Thread Viewer, uses high quality Glass optics. The custom optics were designed and produced by a high-end optics company. As the user adjusts the LED white light, and moves the focusing tube for a clear view, the glass optics bring out the threads in a crisp clear Picture.

Modify

Due to the design of the optics and focal lengths, as you move the Cylinder Thread Viewer deeper into the threads, and into the interior of the cylinder, the inspector can view the under side of the cylinder crown region. As you move the viewer, you can continually adjust the focus. The mirror and optics have a field of view of 2 inches / 5 centimeters. This focusing ability and the brightness of the light allows the inspector to see the underside of the crown, checking for possible cracks or excessive corrosion.

The Cylinder Thread Viewer also can change the diameter of the mirror tube. Two tube sizes can be added to the system. One has a diameter of ¾” / 2cm and one goes as small as ½” / 1.25cm. the inspector can choose the best mirror size for the cylinder they are inspecting.

Simplify

To use the Cylinder Thread Viewer the inspector chooses the size of mirror tube, places an index plate on the top of the cylinder, turns the viewer on and screws the threaded mirror tube into the index plate. The Index plate ensures the mirror tube is stabilized. The index plate threading has been custom designed, to use the least amount of rotations while still allowing multiple passes of the threads while viewing through the mirror. The inspector can remain in one position, the cylinder remains in one position, and the only thing that turns is the Cylinder Thread Viewer.

To help identify areas of concern, the Cylinder Thread Viewer has a custom label on the index plate and an internal laser guiding system. The index plate has a point, which is set on a specific location on the cylinder. For example, the point can be placed on the first letter/number of the serial number. That becomes the “O” point. As the unit is rotated the laser tracks along the index plate. When something is noticed by the inspector, they look at the index plate and records the number on which the laser lands. That allows them to locate the same location when re-assessing the cylinder threads or crown.

This is an excellent tool when identifying the difference between a tap Stop mark and a crack. Review the latest Cylinder Training Services BLOG – Do Not Condemn a good cylinder.

One of the greatest simplification tools added to the Cylinder Thread Viewer is the rechargeable battery. Using a USB-C charging cable you can rapidly charge the unit for 8 hours of continued use. No need to take the unit apart and find batteries for replacement. Simply charge and use. If it is accidently left on, conduct a quick re-charge to continue with the inspection process.

If you are interested in further information on the Cylinder Thread Viewer you can watch the following short video.