I have been diving closed circuit rebreathers (CCR’s) for nearly 20 years now and am qualified to not only dive but teach on a variety of units. Recently I had the opportunity of moving over on to a new unit, that is configured differently from what I normally dive. As anyone that knows me can tell you, I have a thing for rebreathers in general. I also think it’s very important to stay up to date and try new things as well as learn new skills/concepts regardless of your level or experience. I have used or seen a wide variety of weird, wacky, or wonderful ideas/configurations over the course of my rebreather career. What we are now however doing is a paradigm shift from the established norm, and it is these norms that govern and regulate or community. One of the major causes of standards development in the CCR community stems from the early days, where there was very limited amount of production units available. This caused the industry to set standards on equipment that is now outdated and obsolete in many ways.

However, it is these training standards that must be upheld and maintained by instructors to remain compliant with their training agency, and therefore have some protection in the unlikely case of and liability or litigation. For the diver it is just as important as its these training standards that govern your certification at the end of your initial CCR class and this impacts your diving insurance in case of an accident.

Diluent what is it? In the CCR what do we actually need diluent for and how this can be impacted by the type of machine we opt to dive?

Standards and Liability; The small print and how this can effect not only dive professionals and operators but also the individual diver who just wants to enjoy their valuable recreational time having fun diving their rebreather. Then we also need to consider available logistics.

Firstly, what is a diluent, well to answer that we need to understand what a rebreather does. Rebreathers basically replaces the oxygen that is used by the body in metabolism from a source cylinder of 100% oxygen (or as close as possible). Oxygen is our life sustaining gas but as we all know too much of this stuff too deep causes severe risk of oxygen toxicity which can be fatal, therefore if we want to get to any depth on a rebreather, we need to thin the oxygen content down. Diluent does exactly that, it reduces the partial pressure of oxygen, increases breathing volume so it’s comfortable and allows us to increase our depth from 6m maximum to basically anywhere you want to go too! Because of the obvious gas efficiency that rebreathers offer, traditionally the cylinders that we carried on the unit where small with a very finite amount of gas from an open circuit gas consumption perspective. The cylinders used on the CCR’s was typically between 2-3L capacity. Oxygen metabolic rates were calculated on a general rule of 1L/min of oxygen regardless of depth (the marvels of metabolism) so 200bar in a 3L cylinder is 600L of usable gas (no reserve I know) which can be equated to 10 hours of diving at any depth. The diluent is only needed during the descent phase of the dive or when the diver vents gas from the loop, then more gas will be required to equalize the loop volume and allow breathing. Diluent is however also required in case of any kind of oxygen induced emergency, primarily too much oxygen getting in the loop. In this “Oh………Sssshhh!” event, we obviously want to get the oxygen concentration down as quickly and as effectively as possible. For the more traditional approach to rebreather design where the unit was carried on the back and loop volume could be substantial, it was decided early on that the maximum partial pressure of our diluent should be around 1.0bar PPO2 (varies from agency and locality but for the purposes of this we will say 1bar). This decision was made in part by wanting the ability to quickly reduce the loop partial pressure below 1.6bar. If a standard limiting PO2 from open circuit were to be used (1.4bar PO2 traditionally) then you would be using a lot of diluent gas volume to effectively do this, something that you might not have in your small diluent cylinder.

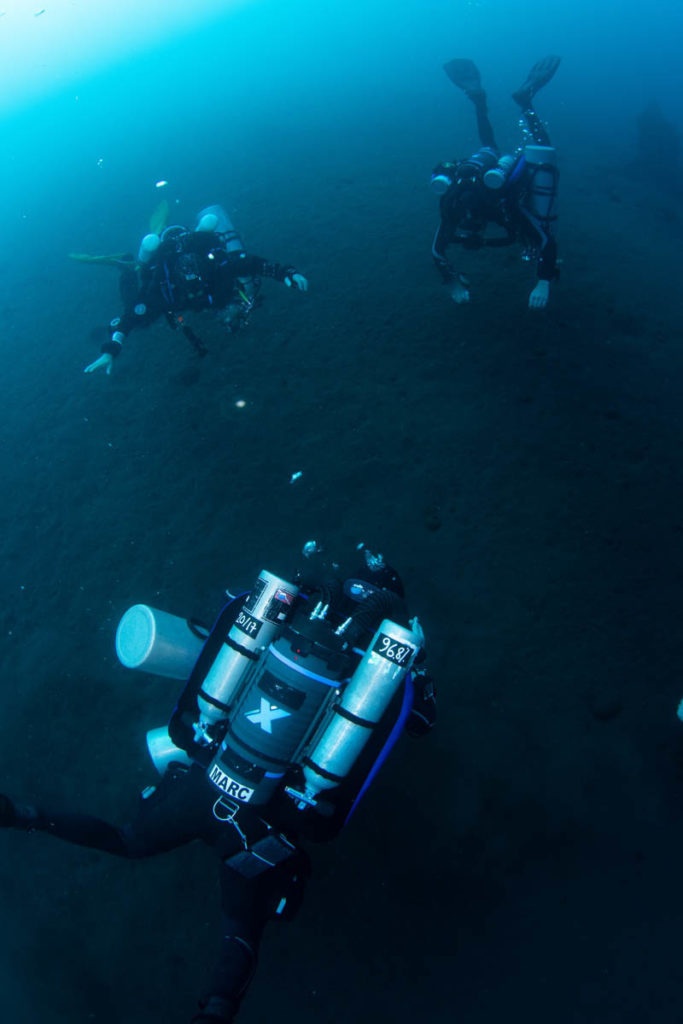

Now if we look at the state of rebreathers today, they are still a niche market but are more common on dive boats and at dive sites worldwide than they were 15 years ago. Also, with more than a dozen different types of units out on the market the technology has developed, the designs are more reliable and improved greatly. Also, with more divers understanding the benefits of rebreathers, units are being used throughout the spectrum of diving from shallow reef filming to extreme deep cave exploration and everything in-between. This has caused unit designers to take concepts and units back to the drawing board. Units are now available in a range of configurations that are optimal tools for the educated explorer.

One of the things that is gaining much greater community acceptance is the “sidemount” style rebreathers. These units differ from the more traditional CCRs by being either on the side of the diver like a side slung/mount stage cylinder or on the diver’s chest. These options are mostly incorporating only 1 integrated cylinder in the actual rebreather and that is the oxygen cylinder, otherwise the rebreather concept wouldn’t work. So now where do we source the diluent from? Rebreather divers have been carrying redundant life support gas back-ups in the form of a tank and regulator, commonly referred to as “Bailout” for years. Something that is also required by all training agencies, is that rebreather divers carry a bailout and the PO2 of this can go up to as high as 1.6bar in open water environments where a direct ascent to the surface is possible. What designers, manufacturers and divers have now started to do is come up with a single solution for these units. Mixing the diluent gas requirements together with bailout gas needs in an emergency this compromise on configuration is being referred to as the “Dilout” solution.

Dilout solutions allow a great deal of flexibility, versatility, and adaptability for the rebreather diver with a mission. Carrying the diluent and open circuit bailout gas requirements in the same cylinder does remove the amount of specialized gear as well as some potential failure points carried by the diver. Running the diluent from the bailout tank will also inevitably mean that the diluent PO2 is higher than the traditionally accepted 1.0bar. This results from wanting to have an effective PO2 for bailout if you were forced off the “loop”. Traditionally the diluent oxygen % had no bearing on your decompression obligation as the rebreather maintains a constant partial pressure of oxygen therefore optimizing any required off gassing obligation. This would not be the case if the rebreather failed, and you would then be following open circuit gas schedules. In this case running a PO2 of 1bar could significantly increase your in-water time as well as the required gas volume to safely exit.

Therefore, the compromise is made, run a higher PO2 than traditionally used with CCR’s. You do need to be sure that you then have adequate diluent gas for recovering the rebreather in the unlikely event of an issue as well as ample bailout gas for a potential rebreather failure. If this has been planned and addressed and depending on the type of CCR you opt to dive, the higher diluent PO2 will also extend the use of your oxygen. This is really only an advantage with the eCCR style units that have oxygen injected via a computer-controlled solenoid valve. Diving a mCCR with a higher dilout PO2 could see slight spikes in PO2 due to the constant trickle flow of oxygen into the breathing loop synomous with mCCR’s. Diving the eCCR with richer Dilout will then see less oxygen being used and therefore having the ability to carry possible smaller cylinders depending on the dive objective and logistics. What happens if the loop PO2 goes high, but the diluent is oxygen rich? Units that are designed and configured to utilize the “DilOut” solution are smaller in overall size, but more importantly the actual breathing loop volume is far smaller than on some traditional units. Therefore, adding gas to a smaller loop from a larger volume cylinder has the same end result as a low PO2 in the small diluent cylinder on larger loop volume traditional unit.

Let’s do a simple calculation to demonstrate, 30m dive using a “Dilout” of 32% means that the PO2 is 1.28bar, therefore at around the desired PO2 set point we want for our dive. This means that for the deepest section of the dive plan it is actually the diluent that can be used to maintain the desired level of oxygen in the loop. As we go shallower the oxygen will again be introduced into the loop via the solenoid to maintain our desired constant PO2. This all sounds pretty straight forward and simple; however, it is still critical to carry enough gas reserve in case of needing to Bailout. This is unfortunately something that a lot of rebreather divers neglect taking into consideration or rely too heavily on the team around them (but that is a different story). I have just used the depth and mix as I way to compare the approaches. On a traditional CCR where the diluent is encased on the unit in a small cylinder and the diver carries a separate bailout system for redundancy. The on-board gas would normally be air and the selected set point in the range 1.2-1.3bar PO2 depending on the dive plan. Now if we assume the set point has been put to 1.3bar even with an air diluent the CCR will be supplying the diver with a nitrox 32.5% (1.3bar PO2 setpoint/4ATA), the diluent is there to reduce the oxygen concentration. The diver would therefore probably select a Nitrox 32% fill for his Bailout. The Dilemma that the diver using a Dilout solution has, is that if air was selected should the diver be forced of the loop due to a problem, then you would be breathing a much less efficient gas mix at a time where you will be needing to expedite your exit from the water. This is mostly likely why as a community we are slowly accepting the concept of “Dilout” however this is something that is not being mirrored in the certification agencies.

The state of standards and the liability game is the big driving force in all areas of diving. Unfortunately, this activity is not risk free, and serious injury or death can be the result of a badly planned dive or misjudged situation. This is another reason why instructors carry 3rd party liability insurance as its the instructors that are at the sharp end in the event of an incident and would need the coverage to pay for fees and potential damages. Training agencies create standards that are approved by insurance underwriters and these standards need to be adhered to by the instructors teaching for that particular training agency. So, here’s the thing, the niche market of rebreather diving has been set up based on the standards developed from the entry of the early units into the market, so a lot of the limits, protocols and procedures base themselves firmly in the more traditional CCR design. Currently the standards set by RESA (Rebreather Education & Safety Association) is limiting the diluent PO2 to max 1.1bar, and even thought this is not the definitive global standard, it is something that most training agencies also base their standards on. The ISO standards for rebreathers is currently being finalized, but this will also be based largely on the RESA recommendations. This basically means that currently there are no amendments being considered for units that do not utilize a traditional onboard gas (oxygen/diluent) approach but instead are designed and configured to run a “Dilout” solution. Therefore, if we opt to dive a “dilout” solution where does this leave us in case of an accident or incident? Will our insurance cover us or is it a get out of jail free card for the policy suppliers?

Standard gases are also something that make the diluent dilemma even trickier. Depending on where you are diving and the logistics available getting a particular fill may be difficult. I switched to just running either Nx32% or Trimix a few years back and very rarely have good old-fashioned air around. This traditionally is no big deal as I prefer to run lite trimix mixtures on the CCR below 35m anyway and adding a trimix to a 2 0r 3L cylinder is a no brainer. However, the unit I recently started to dive uses a “Dilout” solution and as I am still building up my experience with it, I am not venturing much deeper than 30m and therefore opt to run a 32%. This increases oxygen efficiency in the small onboard cylinder and gives me lots of effective bailout in case of an emergency, it however does violate the limits of my certification which in the event of an accident could cause issue with my insurance.

Final thoughts, the use of rebreather systems that are designed to be configured and utilize a “Dilout” solution will remain and most likely gain popularity. These systems provide a lot of additional gas redundancy and therefore time both during the dive phase as well as in case of eventualities or emergencies. As deeper rebreather diving gains in popularity and bottom times are increased to allow more time documenting wrecks, or marine life so will the drawbacks and limits of carrying multiple cylinders for bailout shift towards utilizing dual or bail out rebreather systems. These bailout rebreather systems will more likely than not run a DilOut solution therefore for the sake of both divers and instructors, do manufacturers need to approach training agencies and clarify the PO2 problem for diluent?

Ultimately the buck stops with us the divers as we need to constantly be aware of our level of knowledge and experience. Understanding the dynamics of the rebreather that you opt to dive, selecting diluent based on your chosen unit and the specific objective, whilst considering available logistics. Conducting remedial training and signing up to participate in skills updates with an experienced instructor doing the type of dives that you are wanting to do are all critical.